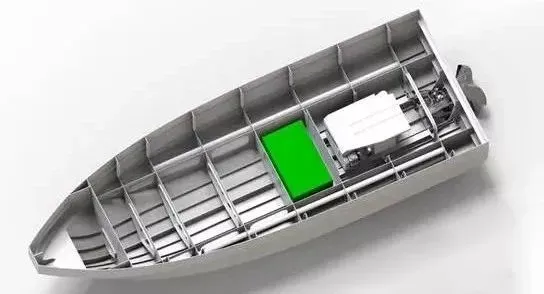

1. Direct Shaft

Direct shaft propulsion is the most traditional propulsion method currently in use. It consists of a rear-mounted engine connected to a transmission device, and the transmission device has a drive shaft that extends directly from the bottom of the boat.

Direct Shaft Yacht Setup

In the photo above, a boat is pulled out of the water, with the shaft protruding from the bottom of the hull. It is supported by a strut right in front of the propeller. The thrust generated by the propeller is controlled by the rudder positioned behind it.

Pros:

- The direct transmission system results in minimal engine power loss.

- The engine is placed more centrally in the yacht, leading to a balanced weight distribution for smoother planning and reduced bow rise.

- It is a very simple setup with the lowest maintenance costs and enhanced reliability.

Cons:

- In some configurations, the necessity to place the engine further forward can lead to a potential loss of cabin

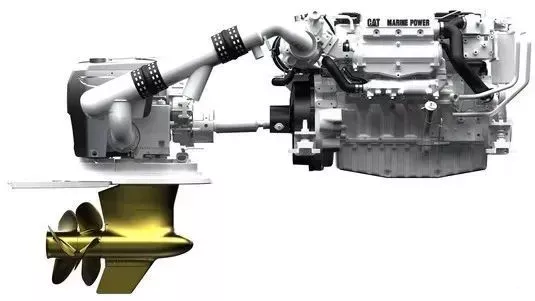

2. Inboard Z-Drive

The Z-drive for inboard yachts features a transmission at the front that directs the drive shaft to the rear. At the bottom of the boat, the transmission looks similar to the direct shaft inside the boat. This application is seen on cruising yachts that aim to maximize interior cabin space.

Pros:

- With the engine positioned further aft, there is more interior space available.

Cons:

- The weight at the stern of the yacht is heavier, and the engine is positioned further aft, which may result in more bow rise.

- With the change in the direction of the Z-drive, there is an efficiency loss from the engine to the propeller.

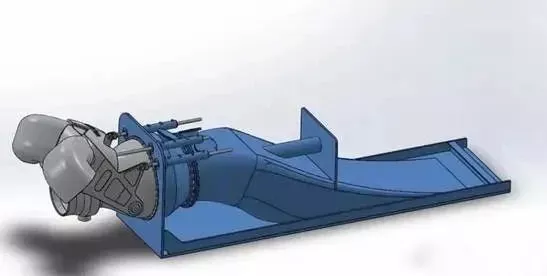

3. Jet Drive

Jet drives are very common in today’s yachts and patrol boats, primarily due to the safety of the propeller (here called an impeller) being inside the boat and the shallow draft. On larger yachts, jet drives are less common than on smaller ones, and they are seen more on yachts that prioritize speed.

Pros:

- Shallow draft and smoother ride.

- Jet drives achieve very smooth operation with minimal vibration by using a small impeller that spins much faster than traditional propellers.

- Higher speeds are possible because the jet drive is located at the stern rather than the bottom of the boat, eliminating the drag from traditional transmission systems.

- More interior space.

Cons:

- Less fuel-efficient than traditional propellers.

- Higher maintenance costs due to many small moving parts that require regular maintenance to prevent failure.

- Poorer maneuverability at low speeds. Without a rudder, the yacht is maneuvered by the thrust of the jet drive, making it less responsive at low speeds when thrust is minimal.

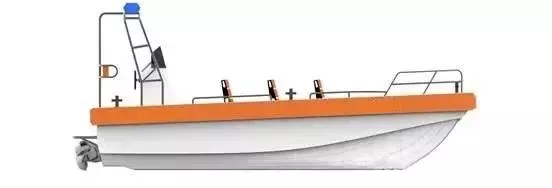

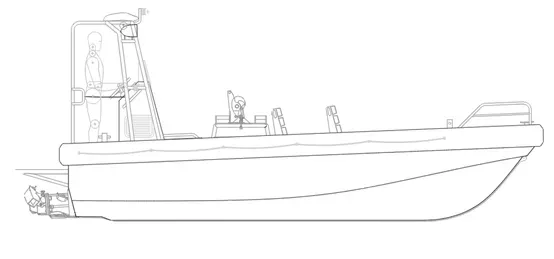

4. Surface Drive

Surface drive yachts share many functional similarities with jet drives. The propulsion unit extends from the stern (transom) of the yacht rather than the bottom, and thrust can be controlled by multiple hydraulic cylinders connected to the shaft. The main difference is that the propeller is outside the boat. They are called surface drives because the upper half of the propeller is exposed above the waterline during operation, reducing cavitation.

Pros:

- Shallow draft with no transmission under the boat.

- More fuel-efficient due to better thrust angles and reduced drag.

- Higher performance with less drag, straighter thrust angles, and larger props.

- More interior space with the engine placed further aft in the yacht.

Cons:

- Higher maintenance costs due to many moving parts that require regular maintenance.

5. Pod Drive

Pod drives themselves are a highly efficient form of propulsion, offering a significant degree of maneuverability and performance. Counter-rotating propellers direct the thrust, and the large gearboxes act as rudders… The yacht’s steering and maneuverability are akin to those of a much smaller sports boat. In addition to these benefits, pods are paired with joystick control systems that independently drive the pods for precise docking and low-speed maneuvering.

Pros:

- More fuel-efficient by 10%-30% compared to traditional shaft drives.

- High-speed maneuverability with direct thrust vectoring as the pods turn.

- Enhanced docking capabilities. Joystick docking functions allow for lateral movement in currents without the need for bow and stern thrusters.

- Position-keeping. Pods controlled by a computer can independently activate to maintain a position using the Global Positioning System, regardless of sea conditions.

- Reduced noise and vibration. Exhaust is discharged underwater to minimize noise, and smaller counter-rotating propellers spinning at higher speeds reduce vibration.

Cons:

- These systems require a multitude of complex mechanical parts and powerful computing… which can increase the cost of the boat by 15%.

- Higher maintenance and repair costs.

6. Outboard Motor

An outboard motor is a type of marine propulsion system that integrates the engine, transmission, and propeller into a single unit, which is mounted externally on the transom of the boat. It is widely used on small boats, but it also has some inherent pros and cons.

Pros:

Ease of Installation and Maintenance:

- Modular Design: The entire propulsion system is a standalone unit, making installation, removal, replacement, or upgrade very convenient. No need to cut holes in the hull for shafts and rudders.

- Easy Inspection: The engine is fully exposed, making all components (spark plugs, carburetors/fuel injectors, water pumps, gearboxes, etc.) easily accessible for routine maintenance and troubleshooting.

- Space-Saving: The engine does not occupy valuable interior space in the cabin (only control lines and fuel lines pass through the hull), making the cabin more spacious or allowing for more cargo/passengers.

Lower Initial and Operating Costs:

- Manufacturing Costs: Generally cheaper than equivalent horsepower inboard systems (including shafts, rudders, etc.).

- Installation Costs: Simple installation with less labor and lower costs.

- Maintenance Costs: Routine maintenance (such as oil changes, spark plug replacements, water pump impeller changes) is relatively easy and less costly (although more frequent).

Lightweight and Efficient (Especially for Medium and Small Boats):

- Weight Distribution: The weight is concentrated on the outside of the stern, which, for well-designed boat types (especially flat-bottomed or V-bottomed small boats), provides good planning performance and high-speed efficiency.

- High Power-to-Weight Ratio: Modern two-stroke and four-stroke technologies offer a high power-to-weight ratio.

- Excellent Shallow Water Adaptability: The propeller and rudder can be easily lifted out of the water or away from shallow areas, making it ideal for navigating in shallow waters, areas with obstacles (such as swamps, rivers, near-shore areas), and avoiding groundings and damage.

Flexible Control:

- Integrated Steering and Reverse: The entire engine unit can rotate left and right (steering) and tilt up and down (reverse/neutral), providing very direct and responsive steering.

- On-the-Spot Turning: Capable of easily performing 360-degree spot turns, offering excellent maneuverability, especially for activities like fishing or docking that require precise control.

- Adjustable Trim/Tilt: The engine’s tilt angle (Trim/Tilt) can be adjusted hydraulically or manually to optimize the boat’s attitude for different loads, speeds, and sea conditions, improving efficiency and comfort.

Greater Freedom in Boat Design:

- No need to design complex structures such as engine rooms, shaft tunnels, and rudders for inboard engines, allowing for simpler and more streamlined hull designs.

Cons:

Lower Fuel Efficiency (Especially at High Speeds):

- Typically, it is less efficient than a well-designed inboard-inboard propeller or jet drive systems at high-speed cruising. Propeller efficiency and drag from engine positioning are partly to blame.

Higher Noise and Vibration:

- The engine is directly exposed to the stern, without the sound insulation and vibration reduction provided by the boat’s structure, making it easier for noise and vibration to transfer to the boat and affect passenger comfort. Modern four-stroke outboard motors have significantly improved in this area but are still generally noisier than inboard engines enclosed in engine rooms.

Exposure to Harsh Environments:

- The entire power unit (especially the lower part) is constantly submerged or exposed to seawater, salt spray, sunlight, and floating debris, posing a very high risk of corrosion and requiring meticulous maintenance (such as rinsing after each use).

Easier to Hit Underwater Obstacles:

- More susceptible to collisions with underwater obstacles (such as wood, rocks, ropes) that can cause damage.

Center of Gravity Issues:

- The weight is entirely hung on the outside of the stern, which for some boat types (especially smaller or poorly matched ones), may affect overall balance and seaworthiness. In particular, on high-horsepower models, it may lead to excessive bow lift or affect high-speed stability.

Horsepower Limitations (Relatively):

- Although modern high-performance outboard motors can exceed 600 horsepower per unit, for very large boats (such as large yachts, workboats), multiple units need to be used in parallel, which may not be as advantageous as a single large-horsepower inboard engine in terms of space, weight, cost, and operational complexity.

Aesthetic Concerns (Subjective):

- Some people believe that outboard motors hanging on the stern are not aesthetically pleasing and disrupt the overall lines of the boat.

External Fuel Tanks:

- Need to carry external portable fuel tanks or install internal fuel.

Outboard motors are ideal for small and medium-sized vessels (especially recreational boats, fishing boats, workboats, and inflatable boats), with their simplicity, flexibility, shallow-water adaptability, space-saving features, and relatively low cost being the greatest advantages. However, they have limitations in terms of high-speed efficiency, noise and vibration control, corrosion resistance, and ultra-high horsepower applications.

7. Inboard/Outboard Drive

Inboard/Outboard Drive (I/O or Sterndrive) is a hybrid marine propulsion system. It installs the engine inside the hull (similar to an inboard engine) and transmits power to an external drive unit (containing the gearbox, propeller, and steering mechanism, similar to the lower half of an outboard motor) via a drive shaft that passes through the stern. This design attempts to combine the advantages of inboard and outboard engines, but it also brings its unique pros and cons.

Pros:

Advantages of Internal Engine Placement:

- Lower noise and vibration: The engine is installed in a closed engine room inside the hull, and the hull structure provides good sound insulation and vibration reduction, significantly improving passenger comfort compared to outboard motors.

- Easier engine maintenance (in some aspects): Large-scale routine maintenance (such as replacing the oil filter, belts, water pump, etc.) can be carried out in a relatively spacious and sheltered engine room, unaffected by weather conditions.

- Better protection: The main body of the engine is protected from direct exposure to sunlight, rain, seawater splashes, and floating debris, reducing the overall risk of corrosion compared to exposed outboard motors (although the underwater drive unit is still exposed).

- More reasonable center of gravity: The heavy engine is located lower and further forward inside the hull (usually in the middle or mid-aft part of the boat), which helps improve the longitudinal and transverse balance of the vessel, enhancing stability and seaworthiness (especially in rough sea conditions).

Good Handling Performance:

- Agile steering: The external drive unit can turn left and right to achieve steering, with a smaller turning radius than a pure inboard engine (with a rudder), offering good maneuverability close to that of an outboard motor.

- Trim/Tilt function: The drive unit usually has a hydraulic lift (Trim/Tilt) function, which can adjust the trim angle and depth of the propeller, optimize the boat’s attitude, improve efficiency and high-speed stability, and facilitate shallow water navigation or towing (such as water skiing).

Space Utilization and Hull Design:

- Releasing stern space: Compared to outboard motors that completely occupy the external stern area, only the drive unit of an I/O is outside, making the stern swimming platform area more complete and providing more available space.

- Optimized hull design: The hull does not need to have holes or protrusions (shaft tunnels) for the shaft and rudder, and the hull lines are usually smoother than those of traditional inboard engines, potentially resulting in lower resistance.

Fuel Efficiency (under certain conditions):

- In the cruising speed range (especially at medium and high speeds), a well-designed I/O system usually has higher efficiency and lower fuel consumption than an outboard motor of the same horsepower. Its propeller position and water flow are closer to the ideal state.

Horsepower Range and Applications:

- Suitable for medium-sized vessels (usually 18 to 35 feet), it can provide greater single-engine horsepower (commonly 200-500+ horsepower) than most outboard motors, offering strong power suitable for boats that require higher speeds and towing capabilities (such as water skiing and fishing).

Cons:

Complex Structure and High Maintenance Costs:

- More complex system: The system includes multiple precision components such as the inboard engine, drive shaft, universal joint, U-joint, gearbox, and external drive unit, increasing the number of potential failure points.

- Difficult and expensive maintenance:

- Maintenance and repair of the drive unit (especially the gearbox and seals) require specialized skills and tools, often involving lifting or removing the entire drive unit, resulting in high labor costs.

- The drive shaft seal (the seal where the drive shaft passes through the hull) is a wear-prone part that needs regular inspection and replacement; otherwise, it can cause severe water leakage. Replacing the seal is a highly specialized and time-consuming operation.

- Repairing and replacement of underwater components (propeller, drive unit housing) are also troublesome and costly.

Poor Shallow Water Adaptability:

- The drive unit and propeller are permanently submerged in water, and their position is deeper than that of outboard motors (usually located after the lowest point of the hull). In shallow water areas or when encountering underwater obstacles, they are highly susceptible to collision damage (gearbox, propeller), posing a much greater risk than the liftable outboard motors. Not suitable for frequent entry into shallow banks, reef areas, or waters with floating debris.

Internal Space Occupancy:

- The engine and its related systems (exhaust pipe, water tank, fuel tank, etc.) are installed inside the hull, occupying valuable cabin space and affecting the layout of passenger cabins or storage areas. The engine room requires a dedicated ventilation system.

Potential Leakage Risks:

- The seal where the drive shaft passes through the hull is a potential leak point; once it fails, it can lead to a large amount of water entering the cabin, posing a risk of sinking. Strict regular maintenance is necessary.

Higher Initial Cost:

- The manufacturing cost of the entire system (engine + drive unit) and the complexity of installation usually make its initial purchase price higher than that of an outboard motor of the same horsepower.

Relatively Complex Steering Mechanism:

- Although steering is agile, the steering mechanism (hydraulic or mechanical cable control of the drive unit’s rotation) is more complex than the direct steering column or hydraulic system of an outboard motor, with more maintenance points. Some older systems have a heavier steering feel (modern hydraulic power steering has improved this).

Corrosion Resistance Challenges (Especially for the Drive Unit):

- The entire external drive unit (especially the aluminum housing) and propeller, which are constantly submerged in seawater, face very serious corrosion problems. Sacrificial anodes (zinc blocks) must be used and regularly replaced, and the unit must be rinsed with fresh water after each use. Improper maintenance can greatly shorten its lifespan.

Winter Storage/Freezing Prevention:

- The engine cooling system in the engine room (usually a closed loop, but with seawater drawn in through the drive unit to cool the heat exchanger) and the internal part of the drive unit both require thorough winterization to prevent freezing and cracking, which is more cumbersome than for outboard motors.

I/O (Inboard/Outboard Drive) is a compromise between inboard and outboard engines. Its greatest strengths are:

- Significantly reduced noise and vibration, enhancing comfort.

- Optimized vessel center of gravity and stability.

- Better fuel efficiency during medium and high-speed cruising.

- Released stern space, providing good handling and Trim/Tilt functions.

- Suitable for medium-sized sports boats, cruising boats, and water-skiing boats that require higher horsepower (single engine 200-500+ horsepower).

However, its fatal weaknesses are:

- The system is complex, with high and specialized maintenance costs (especially for the drive unit and seals).

- Poor shallow water adaptability, with easily damaged underwater components.

- The risk of water ingress due to failure of critical seals.

In short, if you pursue quiet and comfortable cabins, stable hulls, high efficiency at medium and high speeds, mainly operate in deep water, and do not mind complex and expensive maintenance, I/O is a good choice. If you need to frequently enter shallow water, prefer simple and inexpensive maintenance, or have a smaller boat, then an outboard motor is usually a more practical and economical option.